K + S – Bethune Potash Mine Expansion

Location

Parkview, Saskatchewan

Client Name

Project Value

Project Start Date

Project End Date

About

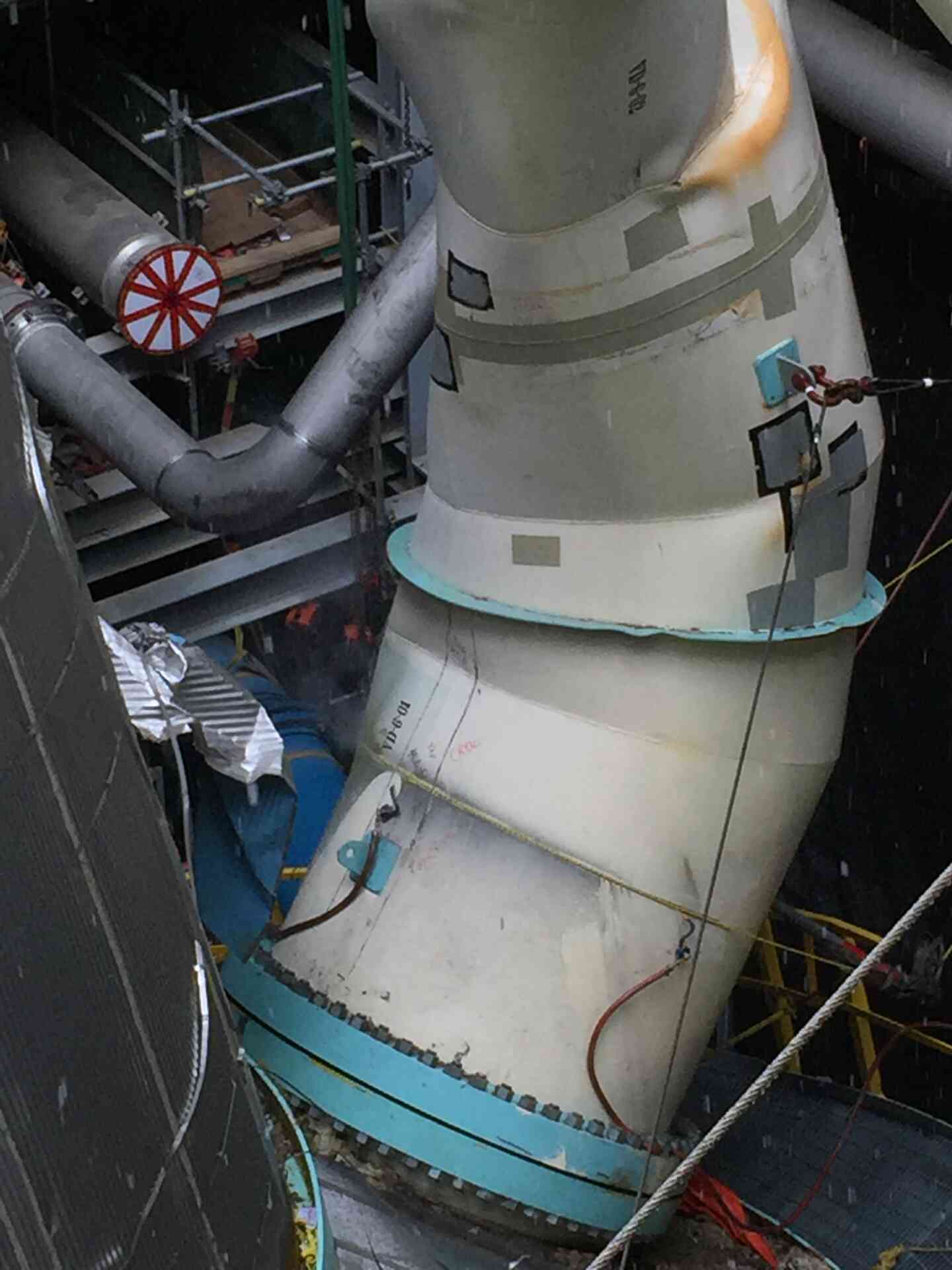

Near the end of construction of the new K+S Legacy Potash processing plant, Waiward was sought out as an independent party to assist with the deconstruction of a compromised support structure for one of the Crystallizer and heat exchanger vessels.

This unique and challenging project required Waiward’s Construction and Engineering departments to collaborate and develop a safe means of removing the compromised components while ensuring the plant could remain functional during this process.

Waiward Scope of Work

Through unique constructability, Waiward navigated around these challenges safely and productively, which positioned Waiward to reinstall all-new support steel, vessels, and the associated process piping and mechanical components including:

- Remove existing roof section above Crystallizer

- Install temporary securement to the compromised components

- Remove collapsed scaffolding via manbasket

- Remove Heat Exchanger Vessel

- Remove compromised piping and electrical components

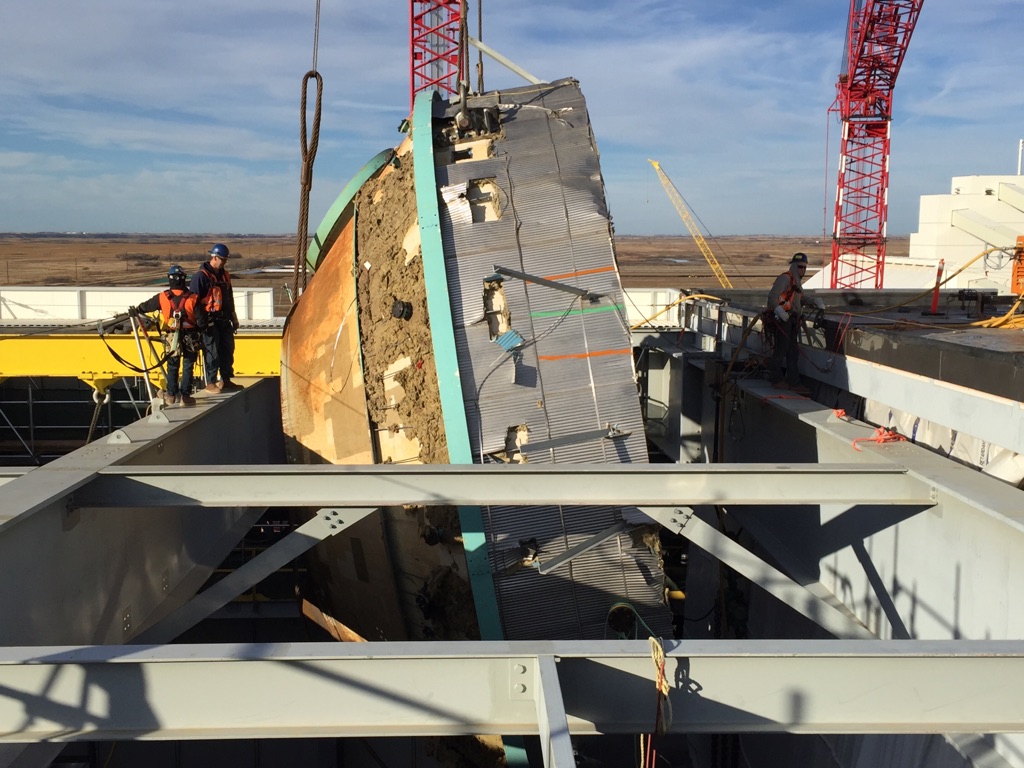

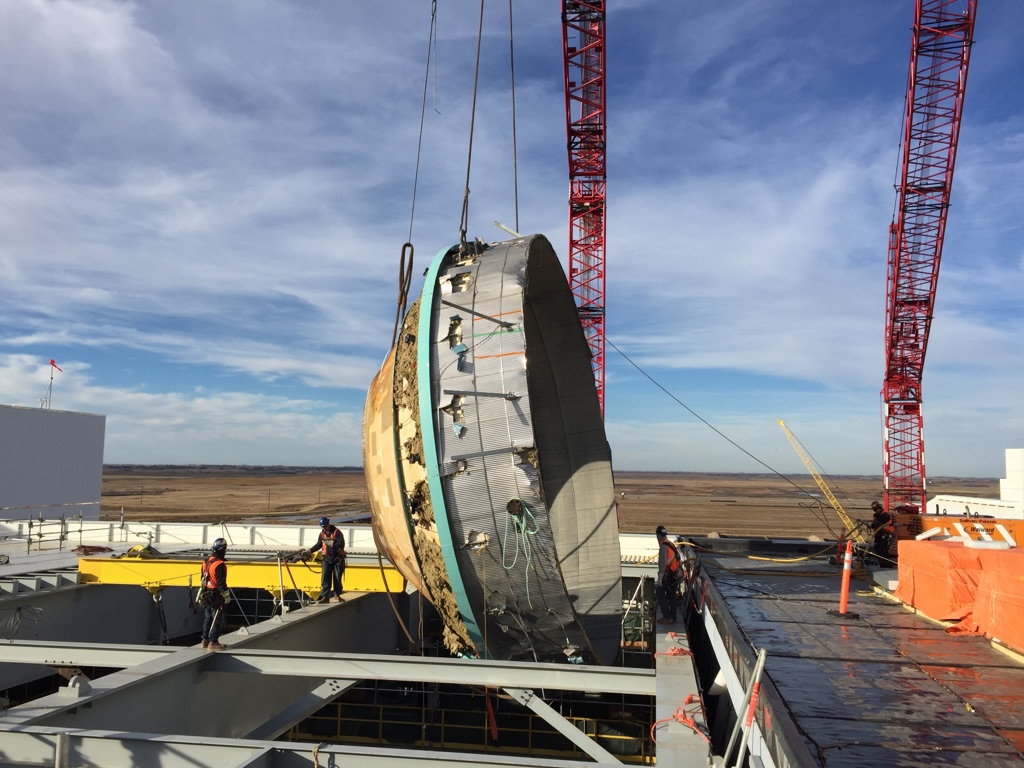

- Utilizing diamond wire “saw” (subcontracted) cut apart the 230MT crystallizer into 5 sections and hoist out of building through the roof

- Work with forensic engineer to methodically remove compromised structural steel components and relocate/stage in forensic storage facility for investigative purposes

- Install temporary support members, remove damaged members from neighboring heat exchanger support structure, and (supply) reinstall new members

Creating Solutions

In addition to the unique nature of this particular scope of work, on of the most challenging/cost prohibitive aspects was the factor that the seasonal wind played. At onset, the wind speeds would prevent efficient usage of the crane hoisting. To work around this, Waiward designed and engineered a large lifting beam that could be set down on the tops of the roof girders which permitted 2 x 50MT pneumatic chain hoists to be hung from underside. This allowed Waiward to progress through the tedious tasked of maneuvering/ untangling the damaged components without being reliant on the cranes.

Once the pieces where free and clear, the crane could rig to the lifting beam and hoist out the various components. The adjustment to the plan, was a main factor in allowing the demolition to be completed within the originally budgeted timeframe.